Water Treatment Case Study – ACO Technologies

From Product Solution to Fabrication Partner

“Collaborating with Cygnet over the years has proven very productive. It is not just the assurance that a high standard of the work will be delivered, but its pragmatic, problem solving, attitude has been a positive contributor in achieving our technical goals.”

Olivier Bouzigars, Technical Product Manager

Project Scope

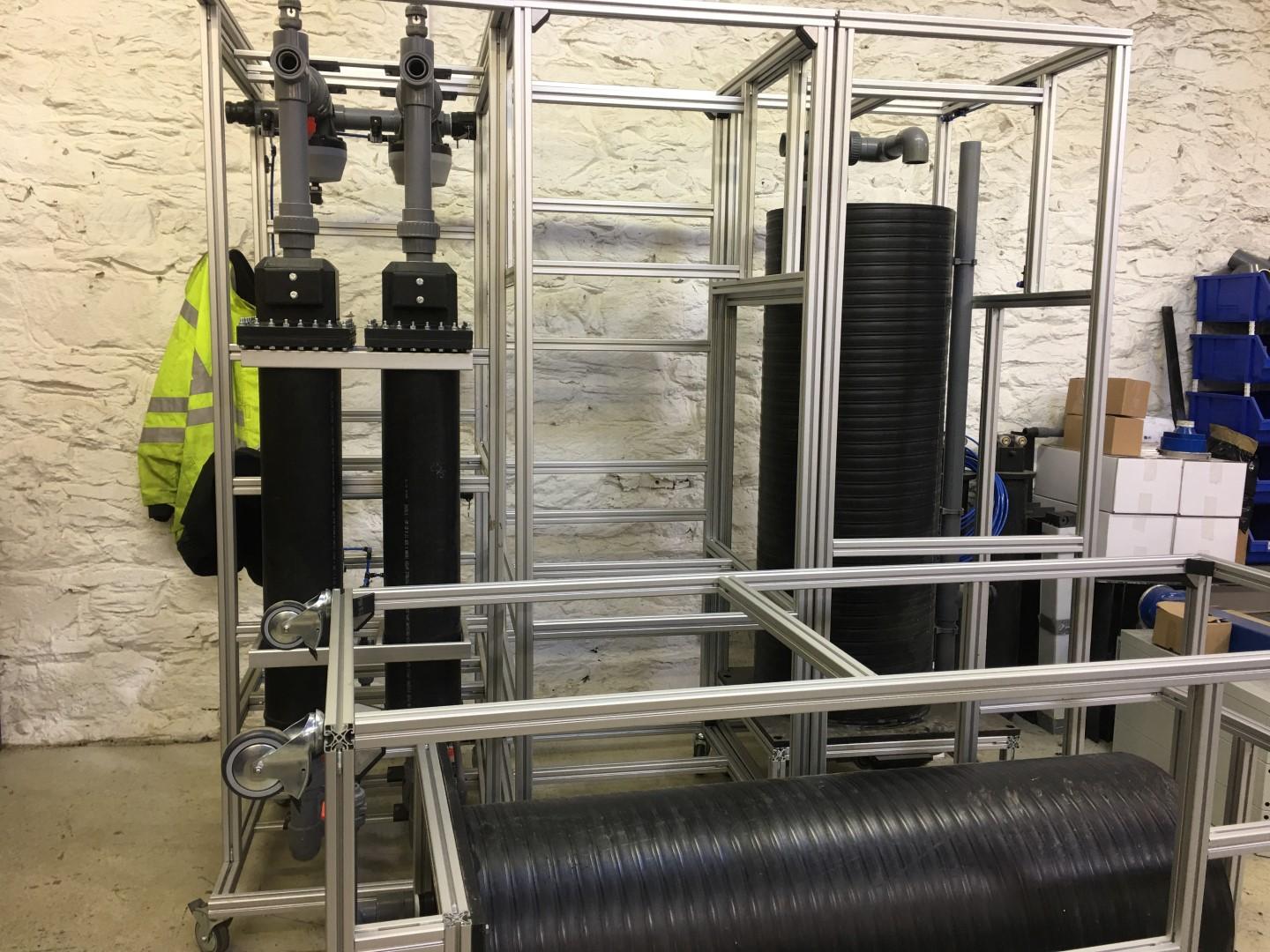

Our original brief comprised developing the simplest of plastic connector fabrications. Our partnership has grown into developing and manufacturing multiple items within water treatment systems including the supply of the largest single fabrication within the company’s UK distribution.

Project Delivery

We work in partnership with ACO identifying possible product development opportunities and responding to in-bound briefs. In hindsight, it’s been simple and our Cygnet qualities and values shine through – meet and exceed our customer expectations each and every time by focusing and aligning with their goals.

Key Elements

- Ensuring development is fit for purpose in the most environmentally friendly range

- No matter the brief or team we work with, the same approach, quality and service is delivered

- The range continues to grow through both Cygnet and ACO’s investment in this relationship

- Products developed and delivered so far include

- Stormwater attenuation connectors

- Stormwater flow control chambers

- Catch-pits

- Hydrodynamic separation chambers

- Quad-receptor chambers

Our Case Studies

You may be interested in our other projects

ELENTEC

BRINGING A CLIENT PROTOTYPE TO MARKET

HYDRO WMS LTD

ENSURING QUICK ACCESS TO BULK AND TECHNICAL PARTS

THE CYGNET PUMP

DEVELOPING THE MARKET LEADING PUMP FOR LANDRILL INDUSTRY